This Privacy Policy for personal data (hereinafter - the Privacy Policy) applies to all information that the site www.panef.ru, (hereinafter -) located on the domain name panef.ru (as well as its subdomains), can receive about the User while using the site panef.ru (as well as its subdomains), its programs and its products.

1. Definition of terms

1.1 The following terms are used in this Privacy Policy:

1.1.1. "Site Administration" (hereinafter referred to as the Administration) - employees authorized to manage the site www.panef.ru, acting on behalf of the Republican Chamber of Entrepreneurs JSC, who organize and (or) process personal data, and also determine the purposes of processing personal data, composition of personal data to be processed, actions (operations) performed with personal data.

1.1.2. "Personal data" - any information relating directly or indirectly to a specific or identifiable individual (subject of personal data).

1.1.3. "Processing of personal data" - any action (operation) or a set of actions (operations) performed using automation tools or without using such tools with personal data, including collection, recording, systematization, accumulation, storage, clarification (update, change), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data.

1.1.4. "Confidentiality of personal data" is a mandatory requirement for the Operator or other person who has gained access to personal data to prevent their dissemination without the consent of the subject of personal data or other legal grounds.

1.1.5. "Site www.panef.ru" is a collection of interconnected web pages located on the Internet at a unique address (URL): panef.ru, as well as its subdomains.

1.1.6. "Subdomains" are pages or a set of pages located on third-level domains belonging to the site www.panef.ru, as well as other temporary pages, at the bottom of which is the contact information of the Administration

1.1.5. "User of the site www.panef.ru" (hereinafter referred to as the User) - a person who has access to the site www.panef.ru via the Internet and uses the information, materials and products of the site www.panef.ru.

1.1.7. "Cookies" are a small piece of data sent by a web server and stored on the user's computer, which the web client or web browser sends to the web server each time in an HTTP request when trying to open the page of the corresponding site.

1.1.8. "IP-address" - is a unique network address of a host in a computer network through which the User gains access to.

1.1.9. "Product" - a product that the User orders on the site and pays for through payment systems.

2. General provisions

2.1. The use of the site www.panef.ru by the User means acceptance of this Privacy Policy and the terms of processing of the User's personal data.

2.2. In case of disagreement with the terms of the Privacy Policy, the User must stop using the site www.panef.ru.

2.3. This Privacy Policy applies to the website www.panef.ru. does not control and is not responsible for third-party sites to which the User can click on the links available on the site www.panef.ru.

2.4. The administration does not verify the authenticity

of the personal data provided by the User.

3. Subject of the privacy policy

3.1. This Privacy Policy establishes the Administration’s obligations for non-disclosure of the personal data provided by the user upon request of the Administration when registering on www.panef.ru, when subscribing to an e-mail newsletter or when placing an order.

3.2. Personal data permitted for processing under this Privacy Policy is provided by the User by filling out forms on the website www.panef.ru and includes the following information:

3.2.1. The User's surname, name, patronymic;

3.2.2. User's contact phone number;

3.2.3. email address (e-mail)

3.2.4. place of residence of the User (if necessary)

3.2.5. delivery address of the Goods (if necessary) 3.2.6. photo (if necessary).

3.3. protects Data that is automatically transmitted when visiting pages:

- IP address;

- information from cookies;

- information about the browser

- access time;

- referrer (address of the previous page).

3.3.1. Disabling cookies may result in the inability to access parts of the site that require authorization.

3.3.2. collects statistics about the IP addresses of its visitors. This information is used to prevent, detect and solve technical problems.

3.4. Any other personal information not specified above (visit history, browsers used, operating systems, etc.) is subject to secure storage and non-proliferation, except as provided in cl. 5.2. and 5.3. of this Privacy Policy.

4. Purpose of collecting personal information of the user

4.1. The User's personal data may be used by the Administration for the following purposes:

4.1.1. Identification of the User registered on the website www.sirep.ru for further authorization, ordering and other actions.

4.1.2. Providing the User with access to personalized data of the www.sirep.ru website.

4.1.3. Establishing feedback with the User, including sending notifications, requests regarding the use of the www.panef.ru website, the provision of services and the processing of requests and applications from the User.

4.1.4. Determining the location of the User to ensure security, prevent fraud.

4.1.5. Confirmation of the accuracy and completeness of personal data provided by the User.

4.1.6. Creation of an account for using parts of the site www.panef.ru, if the User has agreed to create an account.

4.1.7. User notifications by email.

4.1.8. Providing the User with effective technical support in case of problems related to the use of the site www.panef.ru.

4.1.9. Providing the User, with their consent, of special offers, information on prices, newsletters and other information on behalf of the site www.panef.ru.

4.1.10. Implementation of advertising activities with the consent of the User.

5. Methods and terms of processing personal information

5.1. The processing of the User's personal data is carried out without any time limit, in any legal way, including in personal data information systems using automation tools or without using such tools.

5.2. The User agrees that the Administration has the right to transfer personal data to third parties, in particular, courier services, postal organizations (including electronic), telecommunication operators, solely for the purpose of fulfilling the User's order issued on the website www.panef.ru, including delivery of the Goods, documentation or e-mail messages.

5.3. The User's personal data can be transferred to the authorized bodies of state authority of the Russian Federation only on the grounds and in the manner established by the legislation of the Russian Federation.

5.4. In case of loss or disclosure of personal data, the Administration has the right not to inform the User about the loss or disclosure of personal data.

5.5. The administration takes the necessary organizational and technical measures to protect the User's personal information from unauthorized or accidental access, destruction, modification, blocking, copying, distribution, as well as from other illegal actions of third parties.

5.6. The Administration, together with the User, takes all necessary measures to prevent losses or other negative consequences caused by the loss or disclosure of the User's personal data.

6. Rights and obligations of the parties

6.1. The user has the right to:

6.1.1. Make a free decision to provide their personal data necessary for using the www.panef.ru website and consent to their processing.

6.1.2. Update, supplement the provided information about personal data in case of changes in this information.

6.1.3. The user has the right to receive information from the Administration regarding the processing of his personal data, if such a right is not limited in accordance with federal laws. The user has the right to demand from the Administration clarification of his personal data, their blocking or destruction if the personal data is incomplete, outdated, inaccurate, illegally obtained or not necessary for the stated purpose of processing, as well as take measures provided for by law to protect their rights.

6.2. The administration is obliged to:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Privacy Policy.

6.2.2. Ensure that confidential information is kept secret, not disclosed without a prior written permission from the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, with the exception of cl. 5.2 and 5.3. of this Privacy Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this kind of information in the existing business turnover.

6.2.4. Block personal data related to the relevant User from the moment of contact or request of the User, or his legal representative or an authorized body for the protection of the rights of subjects of personal data for the period of verification, in case of revealing inaccurate personal data or illegal actions.

7. Responsibilities of the parties

7.1. The administration, having not fulfilled its obligations, is liable for losses incurred by the User in connection with the unlawful use of personal data, in accordance with the legislation of the Russian Federation, with the exception of cases provided for in cl. 5.2., 5.3. and 7.2. of this Privacy Policy.

7.2. In case of loss or disclosure of Confidential Information, the Administration is not responsible if this confidential information:

7.2.1. Became public domain before its loss or disclosure.

7.2.2. Was received from a third party before it was received by the Resource Administration.

7.2.3. Was disclosed with the consent of the User.

7.3. The user is fully responsible for compliance with the requirements of the legislation of the Russian Federation, including the laws on advertising, on the protection of copyright and related rights, on the protection of trademarks and service marks, but not limited to the above, including full responsibility for the content and form of materials.

7.4. The user acknowledges that responsibility for any information (including, but not limited to: data files, texts, etc.), to which they can gain access as part of the www.panef.ru website, is the responsibility of the person who provided such information.

7.5. The User agrees that the information provided to him as part of the site www.panef.ru may be an object of intellectual property, the rights to which are reserved and belong to other Users, partners or advertisers who post such information on the site www.panef.ru.

The user is not entitled to make changes, lease, transfer on a loan, sell, distribute or create derivative works based on such Content (in whole or in part), unless such actions were expressly permitted in written form by the owners of such Content in accordance with the terms of a separate agreement.

7.6. In relation to text materials (articles, publications that are freely available to the public on the site www.panef.ru), their distribution is allowed, provided that a link is given to.

7.7. The Administration is not liable to the User for any loss or damage incurred by the User as a result of deletion, failure or inability to save any Content and other communication data contained on the website www.panef.ru or transmitted through it.

7.8. The administration is not responsible for any direct or indirect losses incurred due to: use of or inability to use the site or individual services; unauthorized access to the communications of the User; statements or behavior of any third party on the site.

7.9. The administration is not responsible for any information posted by the user on the site www.panef.ru, including but not limited to: information protected by copyright, without the express consent of the copyright owner.

8. Settlement of disputes

8.1. Before going to court with a claim for disputes arising from the relationship between the User and the Administration, it is mandatory to submit a claim (a written proposal or an electronic proposal for a voluntary settlement of the dispute).

8.2. The recipient of the claim within 30 calendar days from the date of receipt of the claim, in written or in electronic form, notifies the applicant of the claim about the results of the consideration of the claim.

8.3. If an agreement is not reached, the dispute will be referred to the Cheboksary Arbitration Court.

8.4. The current legislation of the Russian Federation applies to this Privacy Policy and the relationship between the User and the Administration.

9. Additional terms

9.1. The administration has the right to make changes to this Privacy Policy without the consent of the User.

9.2. The new Privacy Policy comes into force from the moment it is posted on the website www.panef.ru, unless otherwise provided by the new edition of the Privacy Policy.

9.3. Any suggestions or questions regarding this Privacy Policy should be sent to: info@panef.ru

9.4. The current Privacy Policy is posted on the page at http://panef.ru/politika.html

Updated: 16 June 2021

Cheboksary, Republican Chamber of Entrepreneurs JSC

By filling out the form and clicking the "Submit" button, I give my consent to PANEF JSC to process, with or without the use of automation tools, my personal data presented in this application, including collection, recording, systematization, accumulation, storage, extraction, use, depersonalization, deletion and destruction of personal data data for the purposes of processing this request.

I agree to provide me with information about the progress of processing this request through telephone calls, e-mail and SMS messages.

The consent is provided from the moment of registration of this application and is valid for 5 (five) years. Consent may be revoked by submitting to PANEF JSC an application for revocation of consent, drawn up in any form, but containing at the same time an explicit indication of revocation of consent for the appropriate purpose.

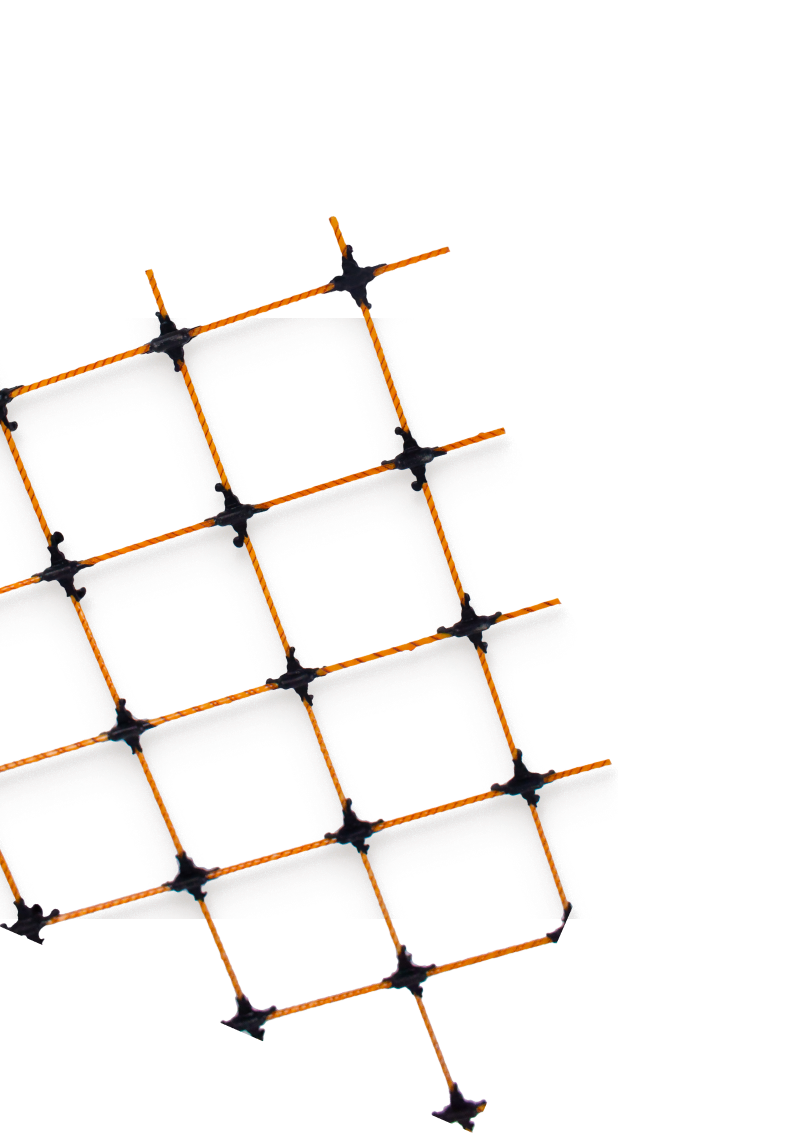

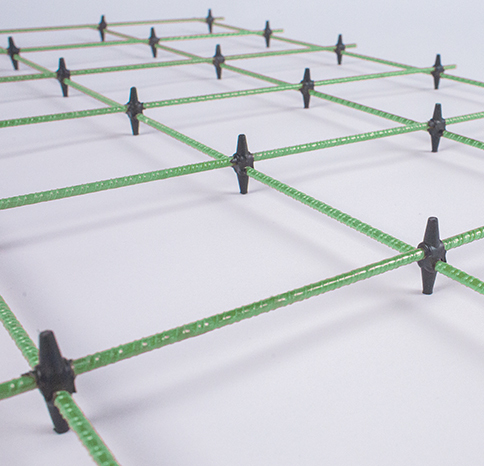

with integrated spacers

more than 300 ° С

The information provided on the site is not a public offer

info@panef.ru